Зајакната чаша завртки на вратот на вратот на вратот

Испрати барање

Strengthened cup head square neck bolts have a cup-shaped head to increase the contact area and disperse the pressure. They are connected to a square neck to prevent the bolt from rotating during installation. After special heat treatment, they can withstand greater tension and pressure.

Product details

They are made of high-strength materials, such as carbon steel and alloy steel. After special treatment, the strength of the bolts is greatly improved. On equipment with large vibrations, they can firmly fix the parts and will not loosen during continuous vibrations, ensuring stable operation of the equipment and reducing the number and cost of maintenance.

Strengthened cup head square neck bolts are used in agricultural equipment. In the field, farm implements like plows are subjected to heavy impacts from rocks and hard soil. The square neck bolt snaps into the implement frame and prevents rotation during intense use. It prevents the bolt from stretching or shearing under the heavy loads and impacts common in agriculture.

It can be used to secure bridge joints. Bridges expand and contract with temperature changes, and these bolts firmly anchor them in the concrete or steel channels, resisting the torsional forces caused by bridge movement. This reduces the risk of failure.

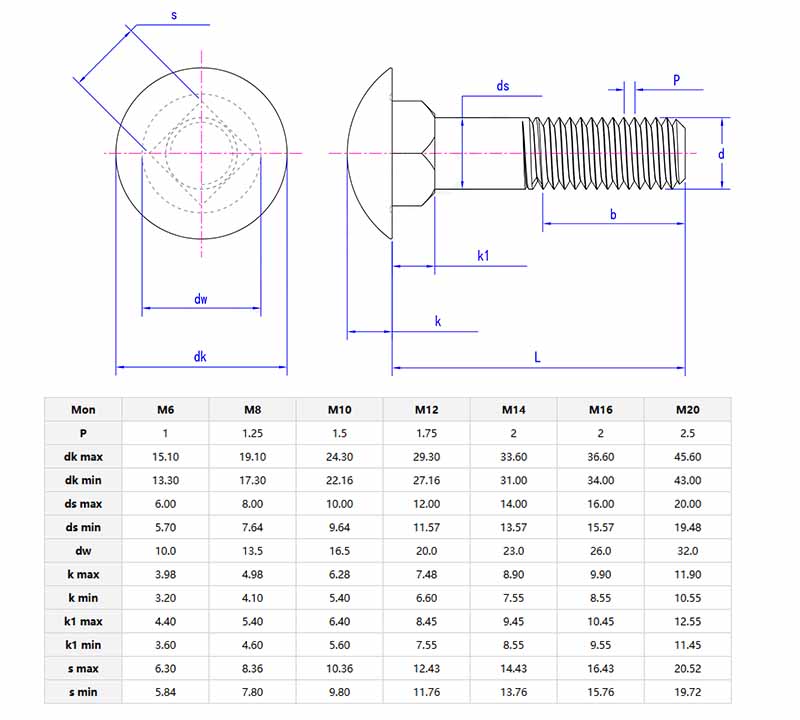

Product parameters

Product feature

The most distinctive feature of the Strengthened cup head square neck bolts is their square neck and cup head. The square neck is like a special key that fits perfectly with the square groove on the material. It plays a role in positioning and preventing rotation during installation. When tightening the nut, the square neck gets stuck in the groove and the bolt won't rotate along, making the installation process easy and efficient. The cup head can evenly distribute the pressure. When fixing thinner materials, ordinary bolts may press indentations or even penetrate the materials. Using them can avoid this situation and also enhance the fixing effect, making the connection more secure.